Eck 3500-up – Eck 3500-HFO

Fully automatic station for recovering, recycling, and recharging R134a or HFO1234yf refrigerant

| Type of refrigerant | R134a o HFO1234yf |

| Service procedure | Fully automatic or manual |

| Voltage | 220-240V 50/60 Hz |

| Scale resolution | 10 gr |

| Oil scale resolution | 5 gr |

| Working temperature range | 11/49°C |

| Filter system | 1 filter for humidity (112 g) |

| Vacuum pump | 100 litre/min capacity, 0.1 mbar vacuum level |

| Compressor | 1/3 HP |

| Recovery speed | 300 g/min in liquid phase |

| Refrigerant tank | 22 litres, refillable (12 litres for HFO) |

| Hoses | 3 meters |

| Dimensions/Weight | cm 55 x 60 x 105 kg. 90 |

| Dimensions/Weight Packaging | cm 70x70x122 kg.100 |

| Thermal printer | Standard equipment |

| Pressure gauges | Class 1 |

| Bottle heater | Standard equipment |

STANDARD FEATURES

ECK 3500 / ECK 3900 ECOTECHNICS FOR HFO1234yf OR R134a

ECK 3500 / ECK 3900 ECOTECHNICS FOR HFO1234yf OR R134a

The A/C service station with all common features. Its standard functions allow a high level of user comfort via the 5“ LCD display. Additional options offers several upgrade opportunities. Available for the refrigerant R134a or HFO1234yf.

ECK-3500/3900 – Fully automatic A/C service station for recovery, recycling and recharging with the refrigerant HFO1234yf or R134a. The high refrigerant recovery rate ensures today’s undeletable contribution to environmental protection.

ECK-3500/3900 – Time savings during work processes. The patented and very compact aluminium recovery unit makes the A/C service station unique and fast. Lines and distances are shortened thereby increasing efficiency and reliability. The working time is noticeably shorter, whereby the high working speed does not decrease even with high outside temperatures and very strong use. After the specification of all automatic or manual work steps by the operator, all processes are fully automated. No service valves need to be operated.

ECK-3500/3900 – Comfort and security. The 5“ LCD display guarantees easy and intuitive menu navigation, with a graphical representation of the procedures and selection of possible options with a short description. The data input is made on a separate keypad with additional function buttons. The menu navigation is something special and guides inexperienced users safely through the A/C service.

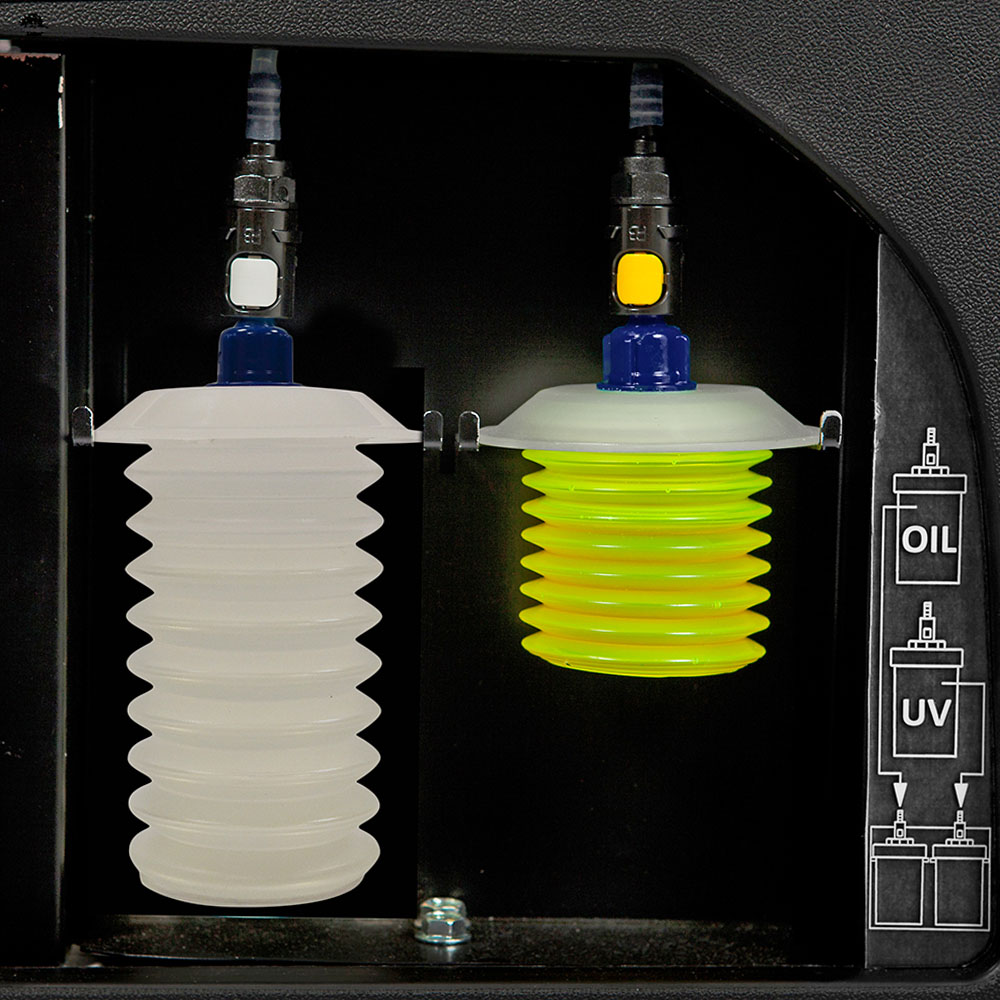

ECK-3500/3900 – The patented hybrid function for electrically driven compressors, is a very efficient cleaning system for service couplings, service hoses and the internal lines. Thanks to this technology, the device can handle very cleanly the compressor oils of the A/C system in the vehicle. Even residual oil quantities between the hermetically and refillable containers and the oil injection valve in the device are eliminated.

ECK-3500/3900 – Clean handling of compressor oil of various standards and types. There are two hermetic containers for the respective refrigerant installed which excludes moisture absorption through hygroscopy of the oil media. The option of hermetic and refillable containers offers further advantages: the user is independent of the supplier, has a high level of user comfort and is future- oriented.

ECK-3500/3900 – The pressure test with forming gas or nitrogen provides optimum security and is factory standard. The test gas is fed into the machine via a connection with a maximum pressure of 15 bar. Via a menu item in the software, the operator can check the vehicle A/C system in overpressure. The holding time and the threshold value for the pressure loss test are specified by the operator in the settings. After the check, the logging takes place and a report is printed out.

ECK-3500/3900 – Flexibility and upgrade with gas identification. The machine can be upgraded within 10 minutes with our gas identification device, thus protecting the machine from contaminated refrigerants. This aims to reach advantages in safety, environmental protection and helps to avoid unexpected costs due to repair service of the contaminated machined. An increasing aspect for the investment in A/C service stations.

ECK-3500/3900 – The workshop-oriented design is user-friendly and suits to the workshop needs in two versions which also differs in colour. With the blue

ECK3500, the pressure gauges are arranged vertically and the hose storage box is positioned laterally. The grey ECK3900 has the hose storage box and the horizontal pressure gauges on the front of the unit.

ECK-3500/3900 – Functional and automatic! The compensation of the service hose length takes place automatically. The pressure sensors can be calibrated automatically. The discharge of the “non-condensable” gases from the internal tank is automatic.

ECK-3500/3900 – Technology for the benefit of the workshop. The special solution from Ecotechnics for the workshop of today and tomorrow looking for speed and economics. The fully equipped A/C service station with all the solutions to a professional service with the refrigerant HFO1234yf or R134a.